When the lights go out, a generator can feel like a lifeline, but its safe operation hinges on one often-overlooked, critical detail: Generator Grounding, Bonding, and Electrical Code Compliance. Get this wrong, and you're not just risking a code violation; you're inviting severe electrical hazards, equipment damage, and even electrocution. This isn't just about plugging in a machine; it's about integrating a powerful electrical source safely into your world, whether it's powering a single appliance or your entire home.

It's a complex topic, rife with misconceptions, but understanding the basics of grounding and bonding according to the National Electrical Code (NEC) is paramount for anyone using a generator. This guide will demystify the rules, help you understand the core concepts, and empower you to make informed, safe choices.

At a Glance: Your Generator Grounding & Bonding Cheat Sheet

- It's About Connection, Not Just the Generator: How you connect your generator to a load (especially a building) determines its grounding requirements. The generator itself isn't inherently "Separately Derived" or "Non-Separately Derived"—its system is.

- Two Main System Types: You'll either have a Separately Derived System (SDS) (neutral is switched, isolated from utility) or a Non-Separately Derived System (non-SDS) (neutral is uninterrupted, connected to utility). This distinction is EVERYTHING.

- One Bond is Key (Usually): For most residential setups (non-SDS), there should be only one neutral-to-ground bond in the entire system, typically at your service panel. Adding a second bond on a non-SDS generator creates a dangerous "parallel path."

- Portable ≠ Simple: Even portable generators have specific rules, especially when connected to a building.

- Manufacturer Instructions are Code: Always follow your generator's manual. NEC 110.3(B) makes these instructions legally enforceable.

- When in Doubt, Call a Pro: Electricity is unforgiving. If you're unsure, consult a qualified, licensed electrician.

More Than Just "Sticking a Rod in the Ground": Why Grounding & Bonding Are Critical

Grounding and bonding are the unsung heroes of electrical safety. They're not just archaic rules from dusty code books; they are meticulously designed systems that protect life, prevent fires, and safeguard equipment.

- Grounding connects an electrical system to the earth, typically via a ground rod or water pipe. It stabilizes voltage, helps dissipate lightning strikes and surges, and provides a reference point for the electrical system. However, it's crucial to understand that a grounding electrode alone typically doesn't clear a fault.

- Bonding ensures that all normally non-current-carrying metal parts of electrical equipment (like a generator frame, conduit, or appliance casings) are electrically connected to each other and to the system's grounded conductor (neutral) and/or equipment grounding conductor (EGC). This creates a continuous, low-impedance path back to the source.

When a fault occurs (e.g., a hot wire touches the metal frame of your generator), bonding provides the critical low-impedance path for fault current to return to the source, causing the overcurrent protection device (OCPD, like a breaker) to trip. Without proper bonding, a fault can electrify metal surfaces, turning them into deadly shock hazards, and without proper grounding, voltage can become unstable or dangerous.

The Pivotal Choice: Separately Derived vs. Non-Separately Derived Systems

Before you connect a single wire, you must first determine if your generator setup will function as a Separately Derived System (SDS) or a Non-Separately Derived System (non-SDS). This distinction is the bedrock of generator grounding and bonding, defining everything from where you bond the neutral to whether you need an independent grounding electrode. The NEC rules (specifically 250.30(A) and 250.34(A)) are entirely dependent on this configuration.

It's not about the generator itself, but about how its neutral conductor interacts with the utility's neutral conductor.

Understanding Separately Derived Systems (SDS)

A Separately Derived System is one where the generator's power source is electrically isolated from the utility system. For a generator, this almost always means its neutral conductor is switched along with the hot conductors by the transfer switch. When the transfer switch flips to generator power, the utility's neutral is completely disconnected, and the generator effectively becomes the new "service" point.

Key Characteristics & Requirements (NEC 250.30(A) and 445.11):

- Neutral Isolation: The critical feature is that the generator's neutral is electrically isolated from the utility's neutral when the generator is operating. This is achieved by a 4-pole transfer switch (switches all three hot legs AND the neutral).

- System Bonding Jumper: Because the generator is now the "source," its neutral must be bonded to its equipment grounding conductor (EGC) and frame. This bond creates the low-impedance path necessary for clearing ground faults. This is done via a system bonding jumper at the generator or the first disconnecting means (often integral to the generator or transfer switch).

- Grounding Electrode Conductor (GEC): A GEC must be connected from the system bonding point to a dedicated grounding electrode system (like a ground rod or other approved electrode).

- Purpose of the Grounding Electrode in SDS: For an SDS, the grounding electrode:

- Stabilizes the system voltage to earth.

- Provides a path for lightning and surge protection.

- Helps keep the generator frame near earth potential.

- Crucially, it does NOT clear ground faults.

- Fault Clearing in SDS: Ground faults are cleared by the low-impedance path established by the system bonding jumper (connecting neutral to frame), the equipment grounding conductors (EGCs) running throughout the system, and ultimately, the overcurrent protection devices (OCPDs) tripping. The fault current travels from the fault point, through the EGC, to the generator frame, then through the system bonding jumper back to the generator's neutral, and finally back to the source to trip the breaker.

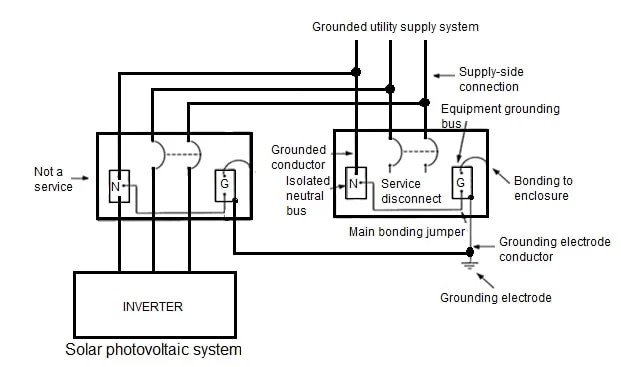

Understanding Non-Separately Derived Systems (Non-SDS)

A Non-Separately Derived System occurs when the generator's grounded (neutral) conductor remains solidly and continuously connected to the utility's grounded (neutral) conductor, even when the generator is supplying power. This is typically achieved with a 3-pole transfer switch, which switches only the three hot conductors, leaving the neutral connected.

The Parallel Path Hazard (NEC 250.6):

This is where understanding the "single bond" rule becomes absolutely critical. The NEC (250.6(A)) strictly prohibits objectionable current flowing on grounding conductors or non-current-carrying metal parts.

- The Problem: If a non-SDS generator has its neutral bonded to its frame (as many portable generators do from the factory) AND it's connected to a building where the utility neutral is also bonded to ground, you've created two neutral-to-ground bonds.

- The Danger: With two bonds, normal neutral current (the return path for power) will split and flow down both the intended neutral conductor and the equipment grounding conductor (EGC) and potentially the generator frame.

- This current flowing on the EGC or frame can energize metal parts, creating a severe shock hazard (NEC 250.4(A)(5)).

- It reduces the fault current on the intended path, potentially preventing overcurrent protection devices (breakers) from tripping during a ground fault. This means a fault could go undetected, leaving an energized, dangerous situation.

- The Rule: For non-SDS systems, the NEC requires only one neutral-to-ground bond in the entire system. This bond is almost always located at the main service panel, where the utility power enters the building.

- Actionable Insight: If your non-SDS generator has a factory neutral-to-frame bond, and you are connecting it to your home (which is a non-SDS setup), you must lift or remove that bond on the generator. Failure to do so creates the dangerous parallel path. This often requires modifying the generator or using a specific type of connection cord that accounts for this.

Navigating Generator Types and Their Specific Rules

The type of generator you have and how you intend to use it dictates which NEC articles apply and, consequently, your specific grounding and bonding requirements.

Portable Generators: The Basic Requirements (NEC 250.34(A))

Portable generators are often the source of the most confusion. Many come from the factory with the neutral bonded to the frame, which is perfectly acceptable for standalone use.

- When a Grounding Electrode is NOT Required: A portable generator does not need to be connected to a grounding electrode system (like a ground rod) IF:

- It supplies only equipment mounted on the generator, cord-and-plug-connected equipment plugged directly into its receptacles, or both.

- The normally non-current-carrying metal parts of the generator and equipment, and the equipment grounding conductor (EGC) terminals of its receptacles, are connected to the generator frame.

- Frame as Grounding Point: Under these specific conditions, the generator's metal frame acts as the system's grounding point, providing the necessary fault path for its onboard and plug-connected loads.

- The Critical Caveat: Connecting to a Structure: The moment a portable generator is connected to a building's wiring system (even via an inlet box and transfer switch), the rules change dramatically. The system now falls under the SDS or non-SDS classification, and the grounding requirements shift significantly. You must re-evaluate the generator's bonding status to avoid the parallel path hazard discussed earlier. If your generator is non-SDS (most common for home connection with 3-pole transfer switch), its neutral-to-frame bond MUST be removed.

GFCI Protection for Portable Generators (NEC 445.20):

For an added layer of safety, receptacle outlets on 15-kW or smaller portable generators are required to have listed Class A Ground-Fault Circuit-Interrupter (GFCI) protection for personnel. This protection can be integral to the generator or part of the receptacle itself. This requirement applies regardless of whether the system is SDS or not, specifically protecting users from ground faults at the receptacle itself.

Trailer- or Vehicle-Mounted Generators (NEC 250.34(B))

These generators share similar characteristics with portable units, but with the added element of the vehicle's frame.

- No Dedicated Electrode Needed (Under Specific Conditions): A grounding electrode is typically not required if the generator's frame is bonded to the vehicle/trailer frame, and it only supplies equipment mounted on the vehicle/trailer or cord-and-plug equipment. The vehicle/trailer frame effectively acts as the grounding point.

- SDS Considerations: If a trailer-mounted generator is used as an SDS (e.g., to power an isolated temporary structure or an event site where the neutral is switched), then its neutral must be bonded to the generator or vehicle frame, and a grounding electrode would typically be required for that specific SDS.

Permanently Installed Generators: The Whole-House Solution (NEC 250.35)

Permanently installed generators are designed to power a home or building automatically during outages. They are always connected through a transfer switch, and their grounding and bonding requirements are more stringent and complex, dictated heavily by the transfer switch type.

- Ground-Fault Current Path: Regardless of SDS or non-SDS, a dedicated equipment grounding conductor must be run with the supply conductors from the generator to the first disconnecting means (usually the transfer switch or service panel). This conductor provides an effective ground-fault current path.

- SDS Configuration: If your permanent generator system uses a 4-pole (switched neutral) transfer switch, it operates as an SDS. This means you must follow all the bonding (system bonding jumper) and grounding electrode conductor (GEC) requirements of NEC 250.30(A) at the generator or the transfer switch. The generator's neutral will be bonded to ground at this point, and there should be no other neutral-to-ground connection within the SDS portion of the system.

- Non-SDS Configuration: If your permanent generator system uses a 3-pole (unswitched neutral) transfer switch, it operates as a non-SDS. In this case, the generator's neutral MUST NOT be bonded to its frame or to ground. The sole neutral-to-ground bond will remain at your main service panel. As per NEC 250.6(A), connecting the grounded conductor to ground simultaneously in both the generator and service sides is strictly prohibited to avoid dangerous parallel paths.

- EGC Sizing: The ground-fault current path conductor from the generator to the first disconnecting means is sized based on the overcurrent protection device's location. If the OCPD is integral to the generator, sizing is per NEC 250.102(D); if external, it's per NEC 250.102(C).

Properly wiring a generator to your house requires careful consideration of these SDS vs. non-SDS distinctions. It’s a job best left to professionals to ensure all code requirements are met for a safe and reliable system.

The Unsung Hero: Manufacturer Instructions and Marking (NEC 110.3(B) & 445.11)

While the NEC provides the overarching framework, your generator's specific design and internal wiring are dictated by its manufacturer. This is why manufacturer instructions are not just suggestions; they are enforceable code. NEC 110.3(B) clearly states that listed or labeled equipment must be installed and used in accordance with any instructions included in the listing or labeling.

- Bonding Status: Manufacturers must clearly mark generators to indicate whether the neutral is bonded to the frame (NEC 445.11). This marking is critical for you or your electrician to determine if a modification is needed for a specific application (e.g., connecting a non-SDS generator to a house).

- Field Modifications: If you or an electrician modify a generator's bonding status (e.g., lifting a neutral-to-frame bond for non-SDS operation), the generator must be re-marked to clearly show its current bonding status. This ensures that future users or technicians understand the generator's configuration.

- What to Look For: Always consult your generator's owner's manual and look for labels on the generator itself. It will often explicitly state if it's "Floating Neutral" (non-bonded) or "Bonded Neutral" (neutral-to-frame bonded).

Common Pitfalls and How to Avoid Them

Even with the best intentions, it's easy to make mistakes that compromise safety and violate code. Being aware of these common pitfalls can help you avoid them.

- Assuming All Generators Are Wired the Same: This is perhaps the most dangerous assumption. As we've seen, whether a generator's neutral is bonded to its frame from the factory varies widely and significantly impacts how it can be safely used. Always check the manufacturer's instructions and the generator's labeling.

- The "Extra Ground Rod" Fallacy for Non-SDS Systems: Many homeowners believe that adding a dedicated ground rod to their portable generator (when connected to the house as non-SDS) is "more safe." In fact, it often contributes to the dangerous parallel path hazard if the generator's neutral is already bonded to its frame. For a non-SDS system, the single neutral-to-ground bond should be at the service entrance.

- Ignoring the Transfer Switch Configuration: The type of transfer switch (3-pole vs. 4-pole) is the ultimate determinant of whether your system is SDS or non-SDS. Overlooking this detail will lead to incorrect grounding and bonding.

- Backfeeding the Utility Grid: This is a deadly practice that, while not directly a grounding/bonding issue, is often a consequence of improper generator connection. Never, ever plug a generator directly into a wall outlet in your home (backfeeding). It sends power onto the utility lines, risking electrocution for utility workers and neighbors, and damaging your home's electrical system when utility power returns. Always use a proper interlock kit or transfer switch.

- Using Undersized or Improper Extension Cords: While not directly grounding or bonding, using inadequate cords can lead to overheating, fire, and voltage drop, which impacts equipment safety and performance. Always use heavy-duty, outdoor-rated extension cords properly sized for the load and distance.

Actionable Steps for Generator Owners

Understanding the code is one thing; putting it into practice is another. Here’s what you need to do:

- Identify Your Generator's Bonding Status:

- Consult the owner's manual.

- Look for labels on the generator (e.g., "Bonded Neutral," "Floating Neutral").

- If unsure, a qualified electrician can perform a continuity test to determine if the neutral is bonded to the frame.

- Determine Your Intended Use & Transfer Switch Type:

- Standalone Portable Use: If you're just plugging in cord-and-plug equipment directly into the generator's receptacles, no external ground rod is typically required (assuming it meets NEC 250.34(A) conditions).

- Connecting to a Building with a 3-Pole Transfer Switch (Non-SDS): If your generator has a neutral-to-frame bond, it must be removed or lifted for this application. The only bond should be at your main service panel.

- Connecting to a Building with a 4-Pole Transfer Switch (SDS): The generator's neutral must be bonded to its frame (or the first disconnecting means) and connected to a grounding electrode system.

- Prioritize Professional Installation: For any generator connected to your home or building's electrical system, hire a qualified, licensed electrician. They will ensure:

- The correct transfer switch is used and installed.

- The generator's bonding status is appropriate for your system.

- All grounding electrode requirements are met.

- All local and national electrical codes are strictly followed.

- Regular Inspection and Maintenance: Periodically inspect your generator and its connections. Check for loose wires, corrosion, or damaged cords. Follow the manufacturer's maintenance schedule.

Frequently Asked Questions About Generator Grounding & Bonding

Let's address some common questions that often arise regarding generator setup and code compliance.

Q: Do I need a ground rod for my portable generator?

A: It depends. If you're only plugging equipment directly into the generator's receptacles, and the generator's frame is bonded to its EGC terminals (which is common from the factory), then no, a separate ground rod is generally not required by NEC 250.34(A). However, if you're connecting the portable generator to your home's wiring system via a transfer switch, then the requirements shift, and an electrician will ensure proper grounding as part of the overall SDS or non-SDS system design.

Q: Can I just plug my generator into a wall outlet in my house during an outage?

A: Absolutely NOT. This is called backfeeding and is extremely dangerous and illegal. It sends electricity backward into the utility grid, potentially electrocuting utility workers, and can cause severe damage to your home's electrical system. Always use a properly installed transfer switch or interlock kit.

Q: How do I know if my generator is a Separately Derived System (SDS) or Non-Separately Derived System (non-SDS)?

A: This isn't determined by the generator alone, but by how it's connected to your home via the transfer switch:

- SDS: Uses a 4-pole transfer switch that switches both hot conductors and the neutral conductor, isolating the generator's neutral from the utility's neutral.

- Non-SDS: Uses a 3-pole transfer switch that switches only the hot conductors, leaving the neutral continuously connected to the utility's neutral.

The generator's manual or labels might also indicate its factory bonding status (bonded neutral vs. floating neutral), which informs how it needs to be configured for a specific system type.

Q: What's the most common grounding/bonding mistake people make with generators?

A: Creating a parallel path for neutral current by having a neutral-to-frame bond on a non-SDS generator while it's also connected to a building's electrical system (which already has a neutral-to-ground bond at the service entrance). This is dangerous because it can energize metal parts and prevent breakers from tripping during a fault.

Q: My generator says "Floating Neutral." What does that mean for me?

A: A "Floating Neutral" generator means its neutral is not bonded to its frame from the factory. This type of generator is ideally suited for non-SDS applications (e.g., connecting to a home with a 3-pole transfer switch), as it inherently avoids the parallel path hazard. For SDS applications, the neutral would need to be bonded to the frame at the first disconnecting means.

Ensuring a Safe & Code-Compliant Power Backup

Understanding Generator Grounding, Bonding, and Electrical Code Compliance is not just academic; it's a matter of life and death. The complexity of these systems, the subtle distinctions between SDS and non-SDS configurations, and the critical importance of manufacturer instructions all underscore one primary takeaway: don't guess when it comes to electricity.

Invest the time to read your generator's manual, understand your transfer switch, and, most importantly, engage with a qualified, licensed electrician for any installation involving your home's electrical system. They have the expertise to navigate the NEC, perform the necessary tests, and ensure that your generator provides reliable power safely and legally. Your peace of mind—and the safety of everyone around you—depends on it.